EN

CINFis

one of the first batch of enterprises awarded Grade A qualification

for general contracting by the Ministry of Construction, has

undertaken the general contracting business since 1985. With the

advantages of technology and management,CINF has

completedplenty of EPC projects, such asthe residence and supporting facilities of the Hunan Provincial

People’s Congress, the phaseIof the Guangxi Pingguo Aluminum Company mine, the second phaseIIof

the smelting of the Shaoguan smelter, and the sightseeing cableway of

Tianmen Mountain in Zhangjiajie, the phaseIof alumina mine of Guangxi Huayin Aluminum Co., Ltd., the phaseIIIof alumina mine of Chinalco Guangxi Branch, the Chongqing alumina

mine project of Chinalco, the Zunyi alumina mine, the phaseIof

zinc oxygen pressure leaching of Danxia Smelter, KivcetPbdirect

smelting projectsetc..TheSureTrak,

P6, Project and other project management software are used in the

project integrated management information system to compile general

contract project schedule plans, resource optimization, dynamic

monitoring and management.

Since 2005, CINFhas been rated as one of the Top 100 National Engineering Contractors every year.

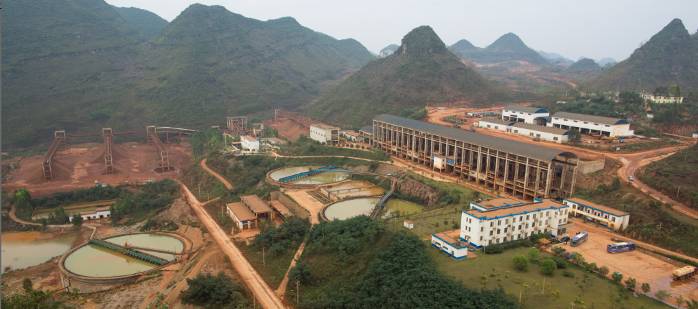

Zunyi

Alumina Mine EngineeringProject

The project has an annual output of 1.7 million tons of qualified bauxite and a total contract amount of 380 million yuan. It is an open-pitmining EPC project, which was officially started on January 9, 2008 and completed in February 2010.

Phase III Mine EngineernigProjectforChinalco Guangxi Branch

CINF operates the Alumina Phase III Mine General Contracting Project (2.02 million t/a Qualified Bauxite) forChinalco Guangxi Branch according to the international general turnkey project mode. Contract amount: 406.75 million yuan. The construction started in November 2006, completed in June 2008 and obtained the performance certificate in April 2009.

Awards

ExcellentEngineering Award ofNonferrous Metals Industry (Ministerial Level)in 2009;

Silver Award for National Excellent Engineeringin 2011-2012.

Alumina Phase I Mine EngineeringProjectforGuangxi Huayin Aluminum Co., Ltd.

Alumina Phase I Mine General Contracting Project forGuangxi Huayin Aluminum Co., Ltd. (3.9 million t/a Qualified Bauxite) isCINF’sfirst project to fully perform its contractual responsibilities in accordance with FIDICterms, and to formally obtain the owner's performance certificate. Contract amount: 1014.198 million yuan. Commencement of work on 25 June 2005; On July 24, 2007, theDebao-mapai mining area was completed. TheJingxi Agriculture and Forestry Mining Area was completed on January 17, 2008. On December 17, 2009, CINFobtained the General Contract Performance Certificate issued by the Owner.

Awards

2010-2011 Luban Award ofChina's Construction Projects (National ExcellentProjects).

The800,000 Tons Alumina Mine EngineeringProjectforChinalco ChongqingBranch

The800kt/a alumina mine project of Chinalco Chongqing BranchisCINF’sfirst large underground bauxite mine managed according to the construction general contracting mode, with a mine production scale of 1650kt/a. The 575 main flat hole with a total length of 8.5 km is currently the longest double-track main transportation lane in the non-ferrous industry. Contract amount: 602.79 million yuan. The construction started on March 18, 2007 and was completed in March 2012.

Awards

The title of Advanced Collective of Key Construction Projects in Chongqing from 2008 to 2010

TheAlumina Phase I Mine EngineeringProjectforShanxi Huaxing Aluminum Company of Chinalco

The project has an annual output of 1.32 million tons of qualified bauxite and a total contract value of 671.86 million yuan. It is an EPC general contracting project entrusted by Chinalco International to CINFfor overall management, and it is also CINF’sfirst entrusted project to accept the production and operation management at the implementation stage by the owner.

TheMaochangMine EngineeringProjectfor Guizhou Alumina Co.

The project has an annual output of 1.2 million tons of qualified bauxite and is an underground mine project entrusted by Chinalco to CINFto implement EPC. Thebauxite deposit is the largest concealed bauxite deposit in China and also one of the important national planning and protection mining areas. The hydrogeological conditions of the mine are extremely complex.The normal water inflow of the mine is 20000m3/d, and the mining technical conditions are complexas well. The belt inclined shaft + trackless ramp are adopted for development, the length of the development roadway is 21000m, and the total contract amount is 619.55 million yuan.

The Duancun-Leigou Bauxite Mining Project ofSanmenxia Mine Section of Chinalco Zhongzhou Mining Co., Ltd.

TheDuancun-Leigou bauxite mine is one of the largest underground bauxite mines in northern China. The mining technical conditions are very complicatedwith the influencefromunstable roof and floor, complicated hydrogeological conditions, numerous old mining tunnels and coal measures strata in the upper part of ore bodies. The design production capacity of the mine is 1600kt/a. The mine is developed by vertical shafts, with 6 lifting shafts and 5 air shafts. The length of the developed roadway is 48000m, with a total contract amount of 980 million yuan.

Awards

High Quality Project Award of China Nonferrous Metals Industry (Ministerial Level) in2016-2017

Technical Upgrading and Reconstruction Project forFankou Lead-Zinc Mine Concentrator

The project adopts a semi-autogenous grinding process, and new raw ore bunker, grinding and floating workshop and rock crushing workshop are built at the existing beneficiation experimental research laboratory and machine repair workshop to replace the existing crushing and screening workshop, fine ore bunker, grinding and lead and zinc flotation workshop. The grinding process of ore washing + semi-autogenous grinding controls the generation of dust from the source. There is only one series of large-scale equipment for grinding and flotation, which changes the current situation that toomany grinding and flotation series, small equipment specifications, large quantity and inconvenient management, and better meets the requirements of large-scale and automation in future concentrators.

General

Contracting Project of Phosphogypsum Slag Storage in Yize Villagefor Sinochem Yumlong Co., Ltd.

The total designed storage capacity of the project is 9.8 million m3, which is the third-class storage. The initial dam height is 53m;the accumulation dam height is 70m, and the total dam height is 123m. Two sets of drainage systems are set up in the reservoir to divert clear and turbid water. The turbid water system adopts the form of drainage well-drainage pipe. The reservoir area adopts "artificial base + anti-seepage membrane" to prevent seepage. The rolling rockfill dam was successfully built with soft rock. The project started in April 2014 and wascompleted and put into use in 2016. The facility is EPC-contracted by CINF.

EPC General Contracting Project for Tailings Transportation in Phase I Mining and Processing Project of Pulang Copper Mine

The tailingsconveyingproject of Pulang Copper Mine Phase I Mining and Processing Project is the first independently designed copper tailings pipeline transportation project with high altitude, high concentration, long distance and coarse particles in China.CINFundertake the project in the mode of EPC project general contracting. The project design adopts three diaphragm pumps with the largest flow rate in the world today in parallel to directly pump copper tailings with an output of nearly 40000t/d and a concentration of more than 55% from the concentrator to the tailings pond, and at the same time directly pump the supernatant of the tailings pond to the concentrator for reuse. The project has a single pipeline length of 32km, the maximum elevation difference of terrain relief exceeds 400m, the flow rate of a single pump is nearly 700m3/h, and the head is nearly 9MPa. The construction site of the project is located in a high altitude and high drop area with an altitude of 3200~3900m. The natural environment is harsh and the construction is difficult. CINFis not afraid of hardships and dangers, abides by its promise and performs the contract perfectlyandhas shaped the "Prang Spirit" and thuswon the title of "Chinalco Xiang Army" given by China Copper Industry.

Awards

High Quality Project Award of China Nonferrous Metals Industry (Ministerial Level) in2017-2018

The General Contracting Project (two phases)of Jiangwan Mud Discharge DamforGuangxi Huayin Aluminum Co., Ltd.

Phase I Project

The designed dam crest elevation is 870m, with a total storage capacity of 20.88 million m3, belonging to the third-class reservoir. Three dams will be built together. The project started in June 2005 and was completed and put into use in July 2007.

Phase II Project

The elevation of twodamsrisefrom 870m to 884m;a new concrete dam is built; and aspillwayis set up. The new storage capacity is about 7.6 million m3;the total storage capacity is 28.48 million m3, and the maximum dam height is 59.7m. The project started in March 2013, was completed and put into use in April 2014, and closed in February 2017.

TheHeightening and Expansion Project EPC General Contracting Project of Longshan Sludge DamforJingxi Huayin Mining Co., Ltd.

CINF

takes the project

in the EPC project general contracting mode. The design is to raise

the dam crest elevation from 880m to 910m in the first phase by 30m,

build 7 dams, increase the total storage capacity by 16.63 million

m3,

and extend the service life by 4.6 years. It was completed and put

into operation in June 2017, and the acceptance expert group assessed

the project as "theleading

in China and first-class in the world".

TheEPC General Contracting Project ofLonghuai Mud Discharge Dam for Guangxi Huayin Aluminum Co., Ltd.

CINF takes the project in EPC project general contracting mode. The elevation of the first phase is 905m and the total storage capacity is 11.46 million m3. The elevation of the dam crest in the second phase is 955m, the maximum dam height is 53m, and the total storage capacity in the final phase is 28.85 million m3, belonging to the third-class tailings pond. The design of the project adopts a series of advanced technical means such as under-membrane drainage, which creatively solves the worldwide problem of "concealed karst collapse and leakage in karst areas" and is praised as "thebenchmarking project of mud discharge reservoir construction project in Guangxi karst areas".

TheGeneral Contracting Project ofLongdong Mud Discharge DamforGuangxi Huayin Aluminum Co., Ltd.

The project has a design elevation of 930m and a total storage capacity of 40.36 million m3. It is a third-class storage. There are 1 inner dam (roller compacted rockfill dam) and 6 outer dams (2 buried rock concrete gravity dams and 4 roller compacted rockfill dams) in the reservoir, with a maximum dam height of 45m. The flood discharge system in the reservoir adopts the type of "drainage well-tunnel". Four sets of groundwater drainage systems are set up in the reservoir to collect groundwater to the tunnel for discharge. The bottom of the reservoir is equipped with double-layer geomembrane to prevent seepage. For the first time, the slope adopts the composite anti-seepage layer of "double-layer geotextile + cement-soil between cloths", which effectively improves the anti-seepage performance of the slope. The project is currently under construction.

TheKIVCET

Direct Lead Smelting with

Zinc Leaching Residue Projectfor Zhuzhou

Smelting Group Co., Ltd.

TheKIVCET Direct Lead Smelting with Zinc Leaching Residue Projectfor Zhuzhou Smelting Group Co., Ltd. (100,000t/a electriclead) is the first project for CINFto introduce new technology of digested lead smelting and undertake EPC general contract. It is also a project that CINFsuccessfully bidsfor and covers the whole process of construction application, survey, design, procurement, construction, training, trial run and reaching the production standard, including the whole process of material preparation, KIVCET smelting, refining and integrated automatic control of electrical instruments, with a contract amount of 628.88 million yuan (excluding 30 million yuan of coppermaterials). The project started in July 2010, was completed in September 2012 and successfully put into operation in January 2013.

Awards

ExcellentQuality Engineering Award ofChina Nonferrous Metals Industry (Ministerial Level)in 2013

TheZinc Oxygen Pressure Leaching Project in Danxia Smelter of Shenzhen Zhongjin-Lingnan Non-ferrous metal Company Limited

The project of Zhongjin-Lingnan Danxia Smelter (100,000 t/a electric zinc and 45,000 t/a sulfur) is the first time to introduce oxygenpressure zinc hydrometallurgy technology in China, and CINFimplement the general contract modeof the project. For the first time, the project adopts large cathode plate and automatic zinc stripping technology, realizing full wet clean production of zinc smelting and sulfur recovery for the first time, and efficiently recovering gallium, germanium and other domestic metals at the same time. The environmental protection, energy saving and comprehensive technical indexes reach the advanced level of the same industry in the world.

TheJCL Gold Concentrate Smelting Project forChina Mining Shaanxi Co., Ltd.

This

is CINF’sfirst case tocooperate

with foreign owners and completely follow the project management

model of western developed countries.

The projectnot only realizes the design idea of new technology, new equipment and new materials, but also successfully applies professional project management software P3 and Suretrak to the dynamic control of the project, ensuring the realization of the owner's project cost and construction period objectives, which is highly praised by foreign managers.

EPC

Project of New Oxygen Pressure Leaching Technology ofWestern

Mining Co.

This

project is an EPC project undertaken by CINFrelying on technological innovation, including two

core parts: oxygen

pressure leaching and sulfur recovery. For the first time, the

project designadopts

an advanced zinc concentrate direct two-stage oxygenpressureleaching processfor electrolyticzinc

production in high altitude and severe cold areas in China. The

electrowinning adopts large cathode plate and automatic zinc

stripping technology. Sulfur is recovered through flotation,to realize full zinchydrometallurgicalenvironmental-friendlyproduction and comprehensively recover valuable metals such as

indium. The project has few and short process, effectively reducing

the energy consumption index per unit product and achieving the

purpose of energy conservation.

Awards

TheFirst Prize for Ministerial-levelExcellent Engineering Design ofChina Nonferrous Metals Construction Association in 2017

Ningde 400,000tCopper Smelting Base Projectof CHINALCO Southeast Copper Co.

This project is a key construction project of CHINALCO Group and Fujian Province. The project adopts the world's most advanced oxygen-enriched intensified smelting (also known as "levitation smelting") technology, andCINFconducts the EPCprojectbased onthe "design management + PC"mode. The project is located in the southeast coast and the plant is builtafter thereclamation project. The construction period is tight and withhighenvironmental protection requirements.

The project was officially started in October 2016, the commissioningwas successful on June 30, 2018, andthefirst batch of anodeplatesweresuccessfully producedonOctober 24, 2018,and the whole production process of the project was completed.

Awards

High Quality Projectof China Nonferrous Metals Industry (Ministerial-level) in2018-2019

Environmental

Protection Upgrading

andRelocationProject of Chifeng Yuntong Nonferrous Metals Co., Ltd.

Thedesign capacityof the project is400,000t/a high purity cathode copper and 1,700,000t/a sulfuric acid. Relying on the advantages of oxygen-enriched side-blownbathsmelting technology and advanced experience in EPC projectmanagement, CINFcontracted the construction of the project based onan integrated project general contractingmode of design, procurement and construction. The main smelting of the project adopts the process of "side-blownbath smelting-top-blowncontinuous converting-electrolytic anode refining-electrowinning",the design integrates many domestic leading technologies such as "patented technology for continuous copper smelting in Jin Fengdualcontinuous furnaces, low-temperature potential heat recovery technology, hydrogen sulfide dearsenization sewage treatment technology", withshortprocess,simple and reliableequipment, highheat utilization rate, torealizeenergy conservation and environmental protection in the whole process of copper smelting. It was rated asthe first industrial benchmark project of CHALIECO.

50,000t/a Electrolytic Manganese Dioxide and 300,000t/a Manganese Sulfate Project (Phase I)of Guizhou Nengkuang Manganese Industry Group Co., Ltd.

ThePhase

I of

the project is an "ecological and environment-friendly green

mine, scientific and technological innovation intelligent mine and

capital operation financial mine" built by Southwest

Energy& Mineral Inc.,CINF

has undertaken the project inEPC contracting

mode.

Advanced BIM technology runs through all stages of the project

design, construction, operation and maintenance. The project design

adopts a series of environment-friendly production technologies such

as large cell electrolysis, enhanced washing of leaching residue,

pneumatic powder transportation, harmonic treatment, etc., and

selects energy-saving equipment such as multi-effect evaporator and

condensaterecovery device to realize efficient environment-friendly production.

The project relyingon intelligent manufacturing technology to build a three-dimensional

visualization platform, highly integrates the automation system of

the production process with the production information management

system, and successfully creates a "intelligentenergy mine".

1000kt/a Copper and Cobalt Slag Comprehensive Utilization Project of Nkana Mining and Resource Processing Co., Ltd.

The project is located in the Chambishi district,Copperbelt Province,Zambia,Africa. CINF has undertaken the projectin the mode of "cost + remuneration"based on EPC management contracting, which is the first overseas EPCproject of CINF. The project adopts advanced oxygen pressure leaching technology to extract copper and cobalt from pyrometallurgical waste slagto produce cathode copper and cobalt hydroxide. The construction period of the project is tight, the distance and time for the transportation of process equipment and materials from China to the project site are long, and the local workers have insufficient technical experience, so the workerscan only take up their posts after training. The EPCcontractofthe project was signed on May 18, 2018.

Zhangjiajie Tianmen Mountain Tourist Highway

Design Year: 1998

ConstructionYear: 1999

Construction Scale: 8K +331 ~ 628 Sections

Zhangjiajie Tianmen Mountain Sightseeing Cableway Project

Theproject is a tourist attractiontourcableway constructed byCINF based ontheproject managementmode. It is currently the longest (7454m) high mountain passenger cableway in the world, one of the few cableways in China with a height difference of more than 1,000m, and the cablewayiswith the largest local slope (37 degrees) in China, and it is also the cableway with the most supports. Contract amount: 188,000,000yuan; Commencement time: March 2002, Completion time: December 2003.

Urban Village Renovation Affordable Housing Projectin Lucheng District,Wenzhou City

Itis a civil buildingproject jointly invested and constructed byCHALIECO andCINF. It is the first project operated by CINF based onBT mode, includingLucheng District Governmentand Dongyu Village two sections,Zhuangtou Reconstruction Plot resettlement housing construction andPutao Village Plot 9-1reconstruction, with thetotal construction area of about 500,000m2.

Hohhot Aluminum Alloy Pedestrian Overpass

DesignYear: 2018

ConstructionYear: 2019

Construction Unit: Hohhot Municipal Engineering Administration Bureau

Construction Scale: sixaluminum alloy pedestrian overpasseswith thetotal length of 235m

Qujing Metallurgical Community (Phase II)

Construction Scale: 77125.82 ㎡

Construction site: Qujing, Yunnan

Construction Unit: Qujing Tuoyuan Real Estate Development Co., Ltd.

DesignYear: 2019

Service Guarantee Center of National Defense University of Science and Technology

Construction Scale: 18849.6 ㎡

Construction site: Changsha, Hunan

Construction Unit: National Defense University of Science and Technology

DesignYear: 2019

Liling Taozihu School

DesignYear: 2020

Construction Unit: Liling Municipal Education Bureau

Construction Scale: 64000㎡

Newly-Built Student Dormitory of Jiangxi Electric Power Vocational and Technical College

Construction Scale: 11,848 ㎡

Construction site: Nanchang, Jiangxi

Construction Unit: Jiangxi Electric Power Vocational and Technical College

DesignYear: 2020

Aluminium Corp all rights reserved by Beijing ICP -1 No. 05024156 Beijing public security 110401000017

Address: the people's Republic of China Beijing, Haidian District Xizhimen North Street No. 62